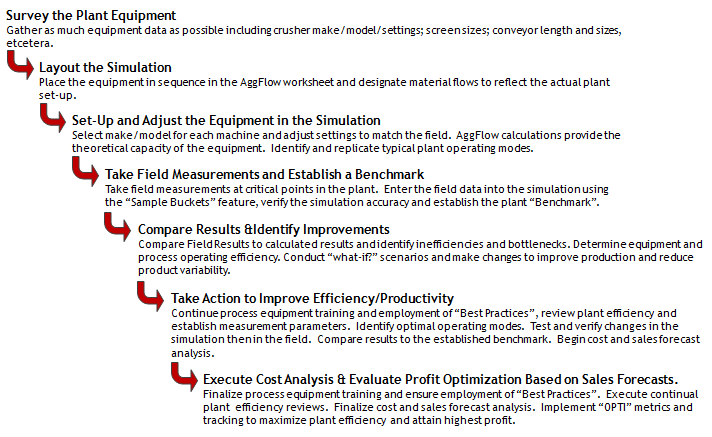

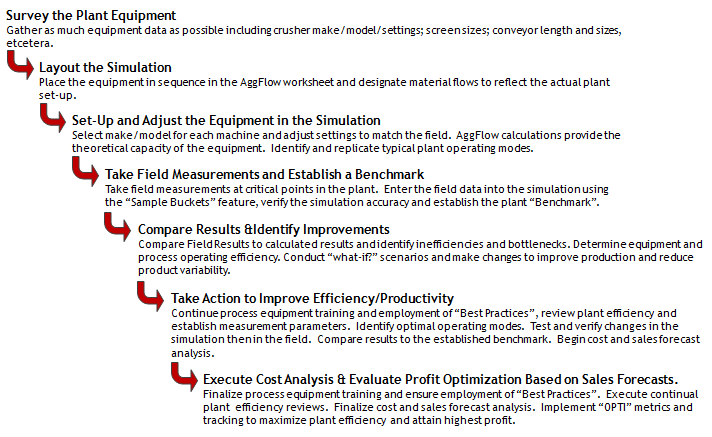

Most aggregate producers know exactly how much material their plant makes. But they often do not know how much it is capable of making. In reality, most plants are under-utilized. By comparing the actual field results to calculated results AggFlow DM users can identify bottlenecks and inefficiencies in the plant, then accurately asses potential changes to maximize plant efficiency and achieve optimum production mix(s).

Aggregate plant simulation requires basic assumptions about the material and equipment be made; is the equipment fully-loaded or under-loaded? is the material wet or dry? hard or soft? AggFlow DM provides the ability to evaluate and simulate plant components and basic assumptions.

AggFlow DM will not miraculously identify why a plant is operating sub-optimally. It will identify and highlight deviation from the theoretical capability of the plant or the established benchmark. Plant managers and engineers can then decide what, if anything, should be done about the deviations and simulate unlimited “what-if?” scenarios to accurately assess the impact of potential changes. Likewise, Equipment Dealers and Consultants can use the program to compare and contrast the impact of different machinery and plant set-ups. The program is also an excellent tool for designing new plants in order to optimize the proposed plant layout and identify what equipment will best meet intended goals.